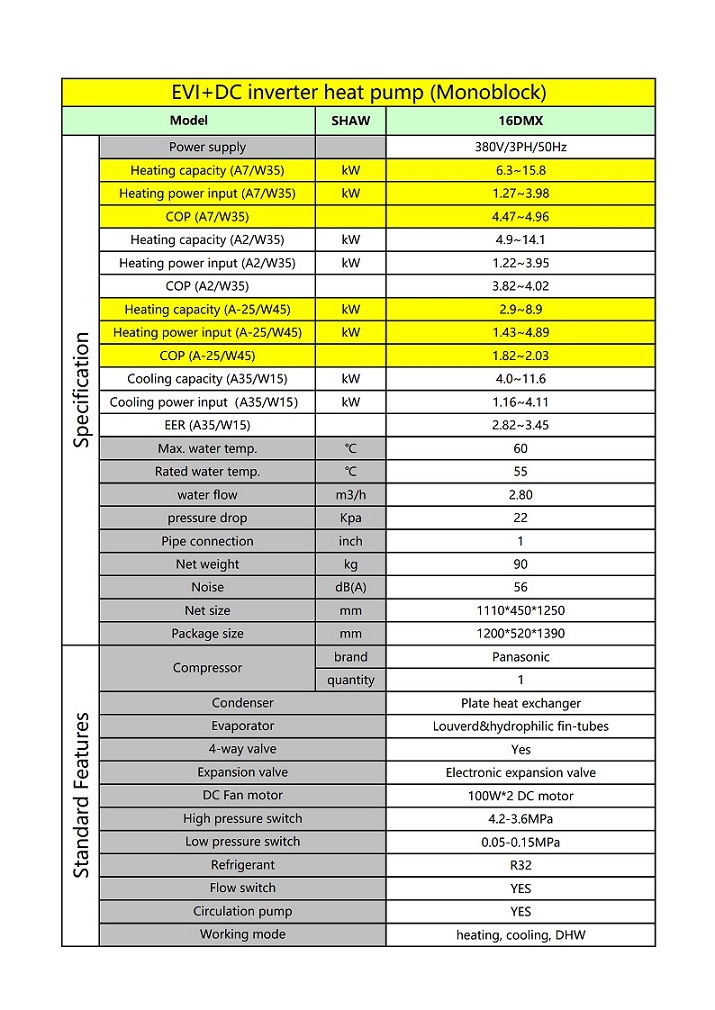

Simple and stylish appearance, powerful functions, environmentally friendly refrigerant R32, can provide 55 degree hot water at -30 degrees Celsius ambient temperature

EVI+DC inverter heat pump, using Panasonic low-temperature variable frequency compressor, plate heat exchanger, built-in circulating water pump, optional electric heater and three-way valve, powerful controller function, WIFI function, with 485 interface, can be remotely connected to control terminal

EVI (Enhanced Vapor Injection) heat pump is a heat pump system that improves low-temperature heating efficiency through intermediate air supply technology, suitable for cold environments. The core principle is to inject compressed refrigerant gas into the compressor, reducing the compression ratio and exhaust temperature, while increasing the system's heating capacity.

The working principle of EVI heat pump mainly adopts a jet enthalpy increasing compressor, which injects medium pressure gas from the economizer during the compression process (such as the middle chamber of a scroll compressor). And an economizer (flash evaporator) is used to divert the liquid refrigerant in the main circuit, which is then depressurized by an expansion valve and evaporates to absorb heat, generating low-temperature steam for gas replenishment.

The main refrigerant enters the evaporator for heat absorption after being throttled by the expansion valve; The branch refrigerant enters the filter and evaporates, providing steam for air supply.

During the working cycle of the DC inverter heat pump, the low-temperature steam generated by the economizer is injected into the compressor through air supply, reducing the exhaust temperature and increasing the refrigerant flow rate to enhance heating capacity. Heat exchange is the efficient heat absorption of the subcooled main refrigerant in the evaporator, which can maintain a high energy efficiency ratio (COP) at low temperatures.

The low-temperature performance advantage of the monoblock heat pump can reduce the compression ratio, supply air to reduce the load of single-stage compression, and avoid the efficiency degradation caused by high compression ratio in traditional heat pumps below -15 ℃. And replenishing air increases the refrigerant circulation, resulting in a 20% -30% increase in low-temperature heating capacity compared to ordinary heat pumps. Supports operation in ultra-low temperature environments ranging from -25 ℃ to -30 ℃ (ordinary heat pumps typically only reach -15 ℃).

The EVI+DC inverter heat pump can also be used for household heating. Choose the variable frequency EVI model, and the variable frequency compressor can dynamically match the load, increasing COP by 10% -15% under partial load. The preferred refrigerant is R410A or R32 (environmentally friendly and with good low-temperature fluidity). Can also be used for commercial/industrial purposes: Large venues require two-stage compression EVI units to further reduce energy consumption through two-stage compression, suitable for -35 ℃ environments. Many EVI heat pumps have integrated designs, such as multi unit collaborative control, to meet the needs of large-scale heating.

The EVI heat pump is suitable for temperatures below -30 ℃ to ensure stability in cold regions, with a heating COP>2.0 (-20 ℃) as the key energy efficiency indicator. The higher the COP, the more energy-efficient it is. The air supply pressure ratio of 1:1.5~1:2 affects the air supply efficiency and compressor life to adapt to load changes.

The air supply pipeline of the monoblock heat pump needs to be shortened and insulated to prevent loss of cooling capacity. Refrigerant filling amount: Accurately calibrated, excessive amount can cause damage to the compressor due to backflow. The filter screen should be cleaned every 2 years to prevent dirt and blockage from affecting air supply.