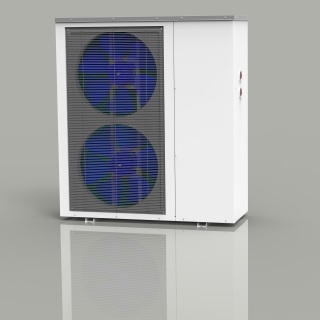

SHAW-45DV DC inverter heat pump

The DC inverter air source heat pump adopts Hitachi DC inverter scroll compressor, which can adjust the allowable frequency of the compressor in real time according to the ambient temperature and water temperature to output the most suitable heat.

DC Inverter Heat Pump Working Model

The working principle of the DC inverter heat pump combines energy conversion processes and technical modules, including step-by-step DC power processing and frequency conversion control. DC input conversion System receives DC from photovoltaic solar cells or mains rectified DC through a DC-DC boost circuit to adjust voltage to the compressor's operating range. Core technology: PWM pulse width modulation technology : Switching transistors operate at high frequencies to chop DC into pulses;

The DC inverter heat pump utilizes inductor energy storage and release, combined with filter capacitors to output stable DC voltage (e.g., boosted to 300-800V DC). Compressor frequency conversion drive Inverter (DC-AC conversion) : Converts high-voltage DC to adjustable-frequency AC to drive the compressor motor . Key process: Control chip (e.g., DSP) generates SPWM waveforms; Full-bridge circuit converts SPWM waves into analog sinusoidal AC; Precise compression speed control is achieved by adjusting frequency (0-150Hz range), enabling 10%-100% infinitely variable regulation.

DC Inverter Heat Pump Core Cycle (Reverse Carnot Cycle): Refrigerant Circulation in Four Steps (Based on the Second Law of Thermodynamics): Evaporation Absorption : Low-temperature liquid refrigerant absorbs heat from air/water source in evaporator, vaporizing into low-temperature gas (heat absorption process); variable frequency compressor compresses low-temperature gas into high-temperature and high-pressure gas, causing sudden temperature rise (main power-consuming stage) ; Condensation Heat Release : High-temperature gas releases heat to water/air in condenser, condensing into high-pressure liquid (heating or hot water);

Air-to-Water Heat Pump Expansion and Pressure Reduction : Electronic expansion valve reduces refrigerant pressure and temperature, returning to evaporator. Heating/Cooling Mode Switching Through four-way reversing valve Reverse refrigerant flow direction: condenser acts as indoor radiator during heating; evaporator absorbs indoor heat (reverse cycle) . New Product Heat Pump Temperature Sampling : Real-time monitoring of environmental, refrigerant, and water temperature parameters; Dynamic Frequency Regulation : Controller (e.g., PID algorithm) compares setpoint and actual values, adjusting compressor/fan speed (e.g., triggers frequency adjustment when room temperature deviates by 1°℃); Low-Temperature Environment Activation EVI jet enthalpy injection technology (compensatory gas enthalpy cycle) enhances heating efficiency at-25°℃. DC Inverter Heat Pump PV Direct Drive Mode: The MPPT controller prioritizes solar energy utilization. Core technological innovations include: Module Traditional Fixed-Frequency Heat Pump DC Inverter Heat Pump . Compressor Control: Start/Stop Mode (Energy Efficiency Ratio ≈2.8) with In-Phase Variable Frequency (COP up to 4.0+) . Temperature Adaptability: Heating Capacity at-10°℃ with-30°℃ Stable Operation (EVI Technology).

Air-to-Water Heat Pump: Energy Utilization: AC Motor + Capacitor Filter Loss Reduced by 10%-20% Conversion Loss with DC Direct Drive . When indoor temperature approaches set point, compressor automatically reduces frequency to low-speed operation (e.g., 30Hz), consuming only 30% of full-load power, achieving "Constant Temperature and Energy Saving" mode.