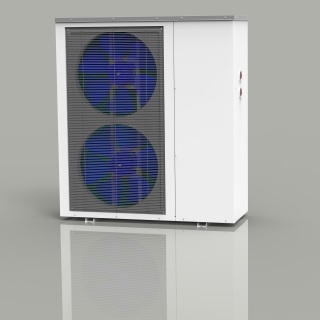

Split EVI Heat Pump (8kW+220V/9kW+380V)

-The 8kW model corresponds to 220V power supply, and the 9kW model corresponds to 380V power supply. Please choose according to the actual situation.

-Suitable for large living room or other large rooms.

Split EVI Heat Pump (8kW+220V/9kW+380V)

8KW/9KW models can meet the heating demand of 50~70 square meters, such as living room, activity room, office, etc.

Please note that the power supply requirements of the two models are different, which shall be selected according to the actual situation and use of the user's region.

The control panel of the indoor unit has an LCD display screen, through which users can easily view the operating parameters of the heat pump and control the heat pump system.

An Air Source Heat Pump (ASHP) is an energy-efficient device that harnesses low-grade thermal energy from ambient air to achieve high-efficiency heating or cooling through the reverse Carnot cycle. Its core operation principle is based on thermodynamic heat exchange and compression cycles, and it primarily consists of four components: a compressor, evaporator, condenser, and throttle valve.

The working principle of EVI Heat Pump involves three key stages: Compression, Heat Absorption, and Heat Release. First, low-temperature, low-pressure refrigerant gas is compressed into high-temperature, high-pressure gas by the compressor. Next, the high-temperature refrigerant absorbs heat from the ambient air in the evaporator during the heat absorption process, vaporizing into a gaseous state. In the heat release phase, the gaseous refrigerant enters the condenser, releasing heat to warm the target medium (such as water or air) before condensing back into a liquid. The throttling process occurs when the liquid refrigerant passes through the expansion valve, reducing pressure before returning to the evaporator to complete the cycle. Key applications include: 1) Household heating/boiling water systems replacing traditional boilers with significantly higher energy efficiency (COP) than electric heaters; 2) Commercial building air conditioning systems that combine cooling and heating functions through four-way valve switching; 3) Industrial heating applications requiring stable temperature control in food processing and pharmaceutical manufacturing; 4) Agricultural greenhouse environments maintaining constant temperatures to promote plant growth.

Air source heat pumps transfer heat between the indoors and outdoors to provide efficient heating and cooling, delivering year-round comfort while lowering energy costs and reducing environmental impact. As a smart, sustainable solution for modern homes, they combine performance, reliability, and energy efficiency

Air source heat pumps are a cost-effective and efficient solution for home heating and cooling. Understanding their operation can help you choose the right system for your needs.

The core principle of air source heat pumps is heat transfer. In winter, they extract heat from the outdoor air and bring it inside to warm your home. During summer, the process reverses, as the pump removes heat from your indoor air and releases it outside, cooling your home. This is achieved through a refrigerant that absorbs and releases heat as it circulates through the system.

An air source heat pump system comprises an outdoor unit, an indoor unit, and a network of refrigerant lines connecting the two. The outdoor unit houses a compressor, a condenser coil, and a fan, while the indoor unit contains an evaporator coil and a blower. The refrigerant flows between these components, carrying heat from the outdoor air to the indoor unit for distribution throughout your home.

Air source heat pumps offer both heating and cooling modes, making them versatile systems for year-round comfort. In heating mode, they draw heat from outside and transfer it inside. In cooling mode, they expel indoor heat to the outside. This dual functionality makes air source heat pumps an energy-efficient and eco-friendly choice for homeowners.